Roll Former Machine for LOSACERO (STEEL DECK)

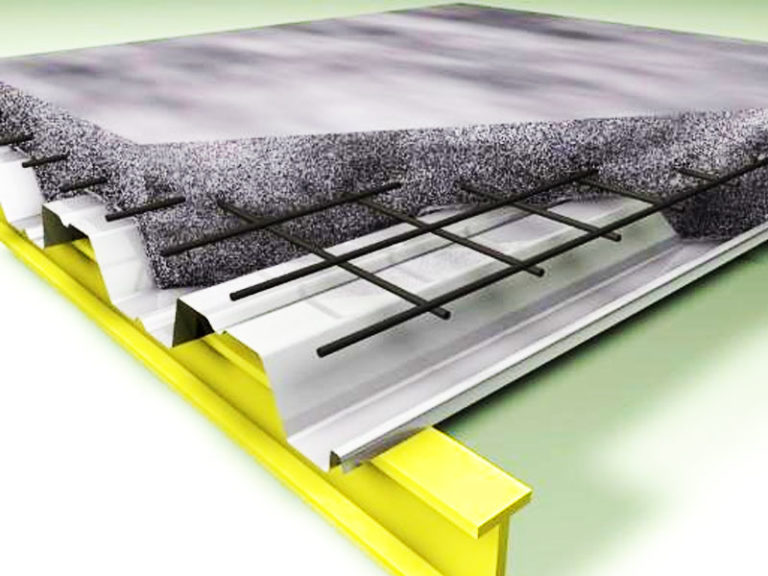

The Losacero (Steel Deck) semi-automated sheet cutting and grooving line is an innovative solution for the construction and metal structure manufacturing industry. Designed to offer high productivity and efficiency, this machine is equipped with advanced features that optimize the steel panel production process.

Main Features of the Machine

Forming Stations

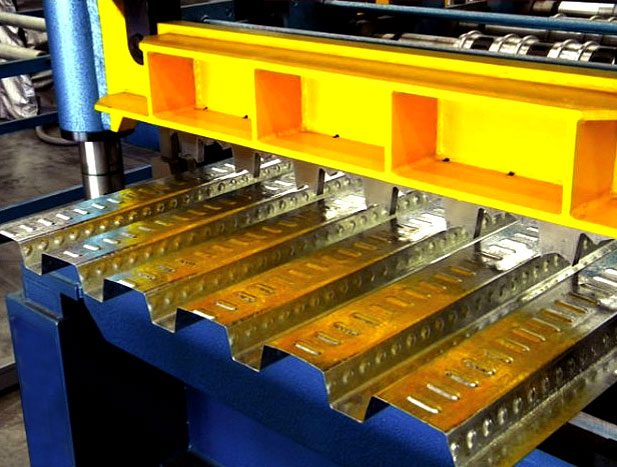

The Losacero semi-automated sheet cutting and grooving line has 24 forming stations (towers), allowing the creation of complex and customized profiles. Each station is designed to ensure precise bending and cutting, adapting to different customer specifications.

Material Engraving Station

One of the distinctive features of this machine is its material engraving station. This allows important information to be marked on the sheets, such as production dates or batch codes, facilitating traceability and quality control of the final product.

High Quality Materials

The rollers of the Losacero semi-automated sheet metal cutting and grooving line are made of 1045 steel, known for its durability and wear resistance. This choice of material guarantees a long machine life and high quality in the finished products.

Powerful Motor

The 20 Hp motor provides the power needed to operate the machine efficiently, allowing it to work with sheet metal gauges ranging from 28 to 20. This versatility is essential for companies that require different specifications in their projects.

Efficient Transmission

The Losacero semi-automated sheet metal cutting and grooving line uses a transmission system composed of sprockets and chains. This system ensures smooth and continuous movement, reducing downtime and increasing production efficiency.

Forming Speed

With a forming speed of up to 20 meters per minute, this machine allows high production volumes to be met in short times. This capacity is ideal for companies that need to meet urgent demands without compromising quality.

Structure and Accessories

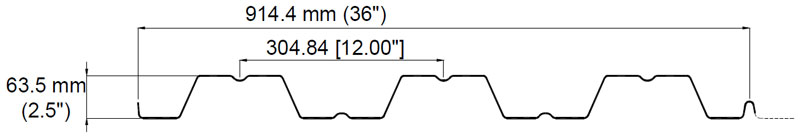

2.5” Depth

The 2.5” depth is a key feature that allows for the creation of strong and sturdy profiles. This design is ideal for applications in roofing and structural construction that require additional support.

General Control Panel

Roll Former Machine For LOSACERO STEEL DECK includes a general control panel that facilitates the operation of the machine. This panel allows the operator to adjust parameters, monitor performance and ensure efficient operation.

Mechanical Roll Holder

The machine is equipped with a mechanical roll holder with a capacity of 5 tons, allowing it to handle large rolls of sheet metal with ease. Although it is not motorized, its robust design facilitates the change and handling of the material.

Hydraulic Guillotine

It includes a hydraulic guillotine with hardened steel blades, which guarantees precise and clean cuts. In addition, the guillotine is designed with the profile shape, which ensures that each cut is made with the correct shape, avoiding waste and improving the efficiency of the process.

Material Receiving Tables

The material receiving tables allow the organization and easy handling of the cut sheets. This is essential to maintain an orderly and efficient workflow in the production plant.

Conditions of Sale and Guarantees

Purchase Process

To acquire the Losacero semi-automated sheet cutting and corrugating line, a 60% advance payment is required, with the remainder to be paid upon delivery or according to agreement. This allows manufacturing to begin and assures the customer that their investment is protected.

Manufacturing Times

The estimated manufacturing time is 4 months, which allows companies to plan their production effectively. It is also important to consider the installation time, which can vary depending on the complexity of the process.

Warranties

The Losacero semi-automated sheet metal cutting and corrugating line has written warranties against manufacturing defects for a period of 2 years. This provides peace of mind to the customer and ensures that any issues are addressed in a timely manner.

Training and Service

Upon delivery, training is offered for staff, ensuring that operators are familiar with all the functions of the machine and can take full advantage of its potential. In addition, the equipment is delivered properly tested, ensuring that everything works correctly before starting production.

Conclusion

The Losacero semi-automated sheet metal cutting and corrugating line is a smart investment for companies looking to increase their production.

You can also find us on our website in Spanish:

https://roladorasmexicanas.com/acanaladora-losacero/

You might also be interested in:

https://rollformer.mx/rollformer-ssr-plus/