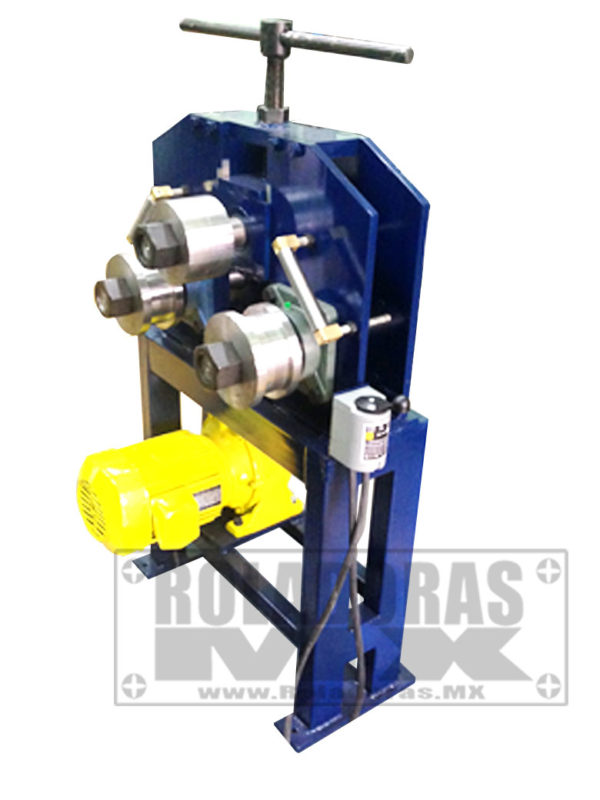

Profile Rolling Machine Innovation and Efficiency in Manufacturing

The profile and tube rolling machine is a fundamental tool in the metallurgical industry, designed to facilitate the bending and shaping of tubes and profiles of various materials. With a series of advanced technical features, this machine becomes an indispensable ally for companies seeking to improve their productivity and quality in the manufacture of metal products.

Main Features:

Robust Construction

The profile rolling machine has a base or structure made of structural and commercial profiles, including a 2” angle base and high-strength A36 plate. The ½” base plate guarantees exceptional stability, even under conditions of intensive use. In addition, the applied industrial paint not only improves the aesthetics of the machine, but also provides effective protection against corrosion and wear, prolonging the useful life of the equipment.

Efficient Transmission System

Our machine is equipped with a transmission system based on a sprocket and chain, which ensures smooth and efficient movement. This system not only optimizes the performance of the machine, but also includes protective covers on the transmission, ensuring operator safety and prolonging component durability.

High Quality Rollers and Shafts

The rollers of the profile bending machine are made of 1045 steel, a material known for its strength and durability. These rollers allow for uniform and precise bending, adapting to different tube diameters and thicknesses. The 2” shafts are treated to withstand significant loads, ensuring that the machine can operate under demanding conditions without compromising its performance.

Working Speed

Our machine offers an operating speed of up to 15 m/min, making it a highly efficient option for projects that require speed and precision. This speed allows operators to meet tight production deadlines without sacrificing work quality.

Advanced Electrical Features

Powerful Gearmotor

Equipped with a 5 hp three-phase gearmotor, the tube bender provides the power needed to perform demanding tube and profile bending jobs. The current required is 220v, which is standard in many industrial facilities, making it easy to integrate into the shop.

Electrical Controls and Hydraulic System

The machine includes a cabinet with electrical controls for the hydraulic system, allowing for simple and effective operation of the machine. This control system includes a pedestal and power cord, ensuring that the operator has easy access to the functions required for tube and profile bending.

Customization and Flexibility

Additional Dies

The tube and profile bender can be customized to each customer’s specific needs. Additional dies for different shapes, such as PTR, angle, square and solid round, are quoted separately, with capacities ranging from 2 to 4 inches. This provides exceptional flexibility, allowing companies to adapt to various projects and production requirements.

Variability in Features

It is important to mention that the characteristics of the tube and profile rolling machine can vary depending on the required capacity. This means that, depending on the production volume and the client’s specifications, adjustments and improvements can be made to the original design to meet specific demands.

Purchase Conditions and Warranties

Purchase Process

To acquire the profile rolling machine, a 60% advance payment is required, which allows the machine’s manufacturing process to begin. The estimated manufacturing time is 4 to 5 weeks, allowing customers to plan their production effectively.

Warranties and After-Sales Service

The tube and profile rolling machine comes with written warranties, which provides additional peace of mind to users when making the investment. In addition, spare parts and technical service are offered, ensuring that any problems can be solved quickly and efficiently.

Conclusion

The tube and profile rolling machine is a valuable investment for any company dedicated to the manufacture of metal products. With its rugged construction, powerful motor and efficient drive system, this machine is designed to deliver exceptional results in bending and forming tubes and profiles.

If you are interested in improving your production efficiency, do not hesitate to consider the tube and profile bending machine as a viable option. For more information and to request a customized quote, we invite you to contact our sales department. We are here to help you.

You can also find us on our website in spanish:

https://roladorasmexicanas.com/roladora-de-tubo/

You might also be interested in:

https://rollformer.mx/drywall-machine/